Let our experts advise you without obligation and secure your competitive advantage with the Demand Planning Tool.

In our non-binding potential discussion, we will show you trends in production and supply chain planning, look at your processes and discuss the sensible use of software-supported planning.

Demand and supply planning for breweries and beverages

Covid-19 has brought the need to map planning processes transparently and digitally into focus: the closure of the catering trade during lockdowns, increased sales volumes in the retail sector and the associated frequent change in container sizes and many other changes have shown companies in the beer and beverage industry the limits of old-fashioned, rough planning processes. The long-lasting trend of falling sales on the German beer market, coupled with increased sales through promotional measures, is also making more precise and flexible planning increasingly important.

FuturMaster, the supply chain planning software recommended in the Gartner “Magic Quadrant”, optimises all supply chain planning processes in the beer and beverage industry.

FuturMaster supports breweries and beverage producers worldwide

Global players such as Heineken, Snow-Beer in China and fast-growing breweries such as Brewdogs rely on FuturMaster for their planning:

The solution: Demand planning with FuturMaster

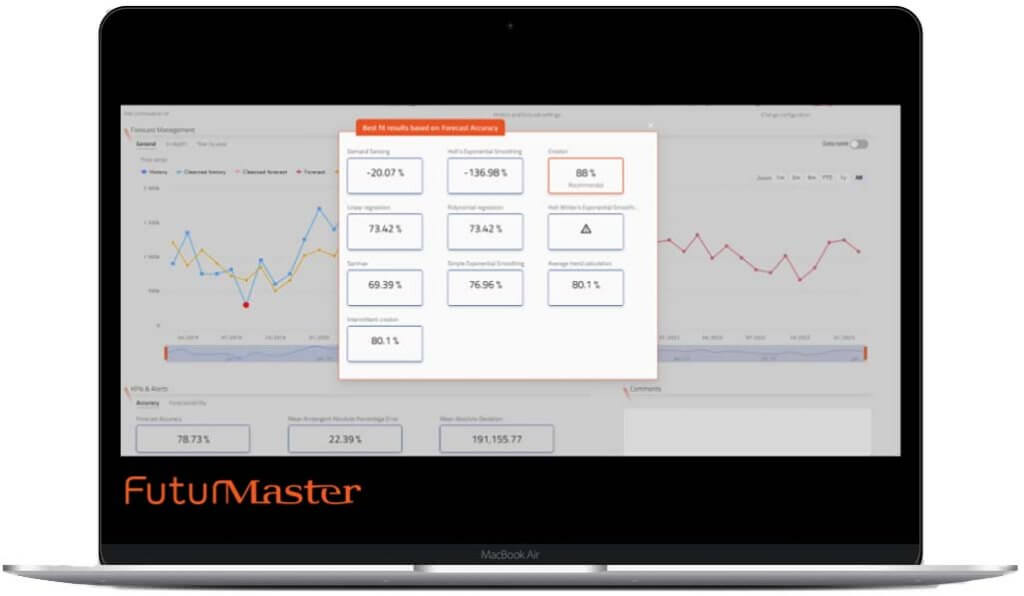

An integrated forecasting and demand planning process is used to determine customer demand in the best possible way as a starting point for the subsequent steps. Both statistical methods and artificial intelligence can be used to predict sales as accurately as possible based on historical data and external variables, such as the “barbecue weather”.

Consistent monitoring of forecast accuracy ensures that the right products are produced and customer segments are served in the best possible way. A separate module for managing promotional measures also helps to make the right decisions here.

The solution: Supply planning with FuturMaster

In modern supply chain planning, mathematical optimisation plays a central role in increasing efficiency and controlling costs. Conventional planning approaches and tools are often not sufficient to optimally solve the increasingly complex interrelationships within the supply chain.

FuturMaster integrates mathematical models to tackle these complex planning problems and find optimal solutions for resource allocation. By using mathematical optimisation techniques, FuturMaster can significantly improve the efficiency of supply chain planning. The optimisation of resources, production capacities and stock levels enables companies to optimally control their production and delivery processes, minimise costs and reliably meet customer requirements.

In summary, FuturMaster’s mathematical optimisation leads to more precise and efficient planning that is based on realistic and dynamic market conditions. This enables companies to be more competitive and not only to master the complexity within the supply chain, but to turn it into a competitive advantage.

Christoph Hansal

Partner, Supply Chain Planning Expert

An integrated supply chain planning solution in just a few months: Thanks to our standardised approach for breweries and beverages, we integrate FuturMaster into your system landscape as part of the project.

Let our experts advise you without obligation and secure your competitive advantage with the Demand Planning Tool.

In our non-binding potential discussion, we will show you trends in production and supply chain planning, look at your processes and discuss the sensible use of software-supported planning.

“State-of-the-art” demand planning based on the following principles

Optimised supply chain planning with FuturMaster

Standardised solution for breweries and beverages

MCP has developed a standardised solution for supply chain planning in the beverage industry with FuturMaster in order to get started as quickly as possible and take advantage of the benefits of FuturMaster. This consists of 4 components and can be put into operation within a few weeks:

Interfaces and system embedding

- Integration of the FuturMaster solution into the existing IT landscape

- Interfaces for automated data exchange with existing systems

- Integration of the data flow based on the defined processes

Demand Planning: Statistical forecasting & machine learning

- Statistical calculation and forecasting for the next 12 to 18 months

- Selection of “best fit” models

- Outliers, trends and recording of unusual events in the statistical model

- Manual and automatic processing of historical data based on the standard solution

Supply planning: mathematical optimisation & graphical analysis

- Modelling of the supply chain based on typical production and filling processes

- Use of standard screens to analyse and evaluate the plan

- Supply Network Visualisation: Graphical processing and problem analysis of the supply chain material flow

Demand Planning: Demand Enrichment & Promotion Planning

- Manual editing of the statistical forecast (“Forecast-Value-Add”)

- Intelligent analyser functions for rapid processing

- Recording of promotional measures

Supply planning: step-by-step optimisation of the plan

- Consideration of all restrictions and constraints

- Fully automated optimisation and decision-making

- Visualisation of all relevant material flow

Reporting & KPIs

- Management cockpit

- Process control cockpit

- Alerting and evaluation option

- Attractive analyses – expandable at any time

Success Story: Supply Chain Planning at Heineken

Heineken: The world’s second largest brewery has been relying on FuturMaster’s supply chain solution for years to optimise its entire supply chain. FuturMaster has been successfully introduced at almost 40 subsidiaries worldwide and helps to continuously improve logistics costs, stock levels, MHD losses and also turnover. Watch the video to find out more about how Heineken successfully manages its supply chain with FuturMaster.

Your production planning and supply chain planning also deserves better! We will be happy to advise you in a non-binding potential check.

Register for a free potential check with just one click:

Our experts will be happy to give you a closer look at the supply chain planning solution for breweries and beverages using a demo.